Knowledge

Differential Probe Operation Guide

In industrial power testing, motor drive debugging, inverter operation and maintenance and other application scenarios, the accurate collection

and analysis of three-phase waveform is the core link to determine the operating conditions of the equipment and troubleshoot potential failures.

Conventional single-ended probes are limited by insufficient common-mode interference suppression,It is difficult to meet the accuracy requirements

in the three-phase system detection because of the defects such as the inability to directly measure the phase-to-line pressure difference.

The differential probe has become the preferred tool for three-phase waveform capture by virtue of its core advantages such as high common mode

rejection ratio (CMRR) and wide range voltage adaptation.

1. Core Concept Analysis: Building a Solid Foundation for Practical Operation

1.1 the core performance characteristics of the differential probe

Differential probe through the synchronous acquisition of two measurement points of the voltage signal, the difference operation to achieve accurate

measurement, its core advantages are:

●Common-mode interference suppression capability: it can efficiently filter out common-mode signals such as power line conducted interference and

space electromagnetic radiation (CMRR is usually not less than 60dB, and high-end models can reach 80dB and above) to ensure the purity of measured waveforms;

●Voltage difference direct measurement capability: without relying on a common reference ground, you can directly collect the line voltage

(such as L1-L2, L2-L3 voltage) or phase voltage (such as L1-N voltage) of the three-phase system;

●Wide range adaptation feature: with switchable attenuation ratio (e. g. 10:1, 100:1, 1000:1), the measurement range can cover 0-7kV or even higher voltage levels,

and can match the measurement requirements of different industrial scenarios such as low voltage 380V and high voltage 7kV.

Core observation parameters of 1.2 three-phase waveforms

In industrial three-phase power supply and drive systems, waveform analysis needs to focus on three key characteristic parameters:

●Voltage amplitude relationship: the amplitude of line voltage (phase-to-line voltage) is √ 3 times of phase voltage (phase-to-zero voltage)

(for example, 380V line voltage corresponds to 220V phase voltage);

●Phase symmetry characteristics: under normal operation, the phase difference of the three-phase waveforms (L1, L2, L3) is strictly 120 °, showing a symmetrical

distribution trend;

●Waveform difference: the power frequency power supply system outputs a standard sine wave, and the inverter outputs a PWM pulse modulation wave.

A differential probe with a bandwidth matching shall be selected according to the waveform form.

2. a step-by-step hands-on process: from wiring deployment to waveform capture

Wiring specification for 2.1 three-phase system (core operation link)

The corresponding wiring mode shall be selected according to the type of three-phase system (three-wire system/four-wire system), the power supply of the

system shall be cut off before wiring, and the correctness of wiring shall be checked with a multimeter before power-on test to prevent short-circuit risks:

(1) Three-phase four-wire system (including zero line N, such as power frequency mains power supply scenario)

Measurement object: phase voltage (L1-N, L2-N, voltage between L3-N)

Wiring steps:

1. Connect the positive input terminals () of the three differential probes to L1, L2 and L3 phase lines respectively;

The negative input terminals (-) of 2.3 probes are uniformly connected to the N terminal of the neutral line;

3. The ground wire (GND) of all probes is connected to the protective grounding terminal (PE) of the system, and suspension grounding is strictly prohibited;

4. The 1, 2 and 3 channels of the oscilloscope correspond to 3 probes respectively, which are used to observe L1-N, L2-N and L3-N waveforms.

(2) Three-phase three-wire system (no zero line, such as motor drive, inverter output scene)

Measurement object: line voltage (L1-L2, L2-L3, voltage between L3-L1)

Wiring steps:

1. Probe 1 configuration: the positive input terminal () is connected to L1 phase line, and the negative input terminal (-) is connected to L2 phase line for measuring

L1-L2 line voltage;

2. Probe 2 configuration: the positive input terminal () is connected to the L2 phase line, and the negative input terminal (-) is connected to the L3 phase line for

measuring the L2-L3 line voltage;

3. Probe 3 configuration: the positive input terminal () is connected to L3 phase line, and the negative input terminal (-) is connected to L1 phase line for measuring

L3-L1 line voltage;

4. Connect the ground wires of the three probes to the protective grounding end of the system to ensure that all ground wires are connected at the same point.

2.2 Oscilloscope Parameter Configuration (Accurately Capture Key Links)

(1) Channel parameter configuration

Enable the three measurement channels of the oscilloscope, and set parameters matching the attenuation ratio of the differential probe for each channel. The

voltage range is set according to the estimated measurement voltage (for example, when measuring 380V line voltage, select 100:1 attenuation ratio probe, the

signal amplitude after attenuation is 3.8V, and the voltage range can be set to 5V/div).

(2)Trigger parameter configuration

Trigger source selection: select 1 of the three phases (e. g. L1) as trigger reference source to ensure synchronous acquisition of three-phase waveforms; Trigger

type adaptation: select "edge trigger" when measuring sine wave, and select "edge trigger" when measuring PWM modulation wave.

"Pulse trigger"; trigger level adjustment: set to about 1/3 of the signal amplitude

(For example, when measuring 380V line voltage, the trigger level is set to about 120V) to avoid false triggering due to interference.

(3) Time base and sampling rate configuration

Power frequency 50Hz waveform measurement scenario: the time base gear is set to 20ms/div (the single cycle of power frequency waveform is 20ms, and this

gear can display 2-3 complete cycles in the 1 screen); Inverter PWM Wave Measurement Scene (Switching frequency 10kHz for example): The time base gear is

set to 100 μs/div and the sampling rate is set to 10MSa/s to ensure accurate capture of pulse details.

2.3 Waveform Capture and Optimization Adjustment

1. After the system is powered on, start the "single capture" or "continuous capture" function of the oscilloscope to observe the waveform stability;

2. If the waveform drifts, fine-tune the trigger level parameters or increase the trigger hold-off time appropriately (for example, the power frequency scenario is set to 10ms);

3. Phase calibration adjustment: take the trigger phase (such as L1) as the reference and ensure that the phase difference between L2 and L3 waveforms and L1

is accurately maintained at 120 and 240 respectively through the oscilloscope phase delay adjustment function;

4. Key area amplification: local amplification of key points such as waveform peak value and zero crossing point (for example, adjusting the voltage gear to 1V/div) is

convenient for subsequent accurate measurement of parameters.

Key Points of 3. Waveform Analysis: Determining System Running Status

3.1 key parameter measurement and standard comparison

Use the "measurement function" of the oscilloscope to extract the following key parameters and compare them with the standard values:

●Amplitude accuracy verification: the peak value of line voltage shall conform to 1.414 times of the nominal value (I. e. √ 2 times), for example, the peak value

of 380V line voltage is about 537V, and the peak value of 220V phase voltage is about 311V;

●Phase difference detection: the phase difference between the L1-L2 and the L2-L3 should be controlled within the range of 120 ° ± 5 °, beyond which there

may be load imbalance or line fault;

●Frequency and distortion characteristics: The frequency of the power frequency power supply waveform shall be stable within the range of 50Hz ± 0.5Hz. The

total harmonic distortion (THD) shall be detected through the FFT analysis function of the oscilloscope. The THD shall be ≤ 5% under normal working conditions.

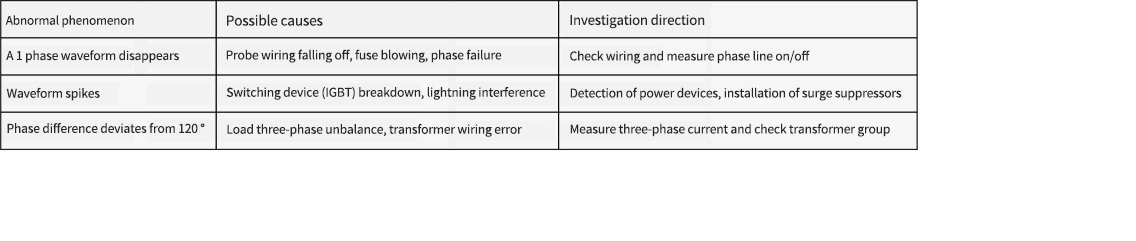

4. Abnormal Diagnosis